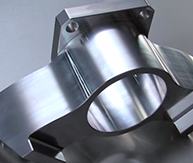

There are countless ways to improve productivity on your Haas machines, and one is as simple and cost-effective as replacing standard flood coolant with a high-pressure coolant system. The most obvious advantage of high-pressure coolant is that it enables faster and deeper cuts than with flood coolant. But there’s much more:

Read MoreLocal News & Events | Haas Factory Outlet

5 Reasons To Add High Pressure Coolant Delivery To Your CNC Machine

Posted on Mar 17, 2017 12:00:00 AM

Tags: Productivity, Maintenance Tips

Haas CNC machines and the Haas Control have many ways to help your shop reduce production costs and avoid machining mishaps. In this video you’ll learn how to use the G98 and G99 canned cycles and clearance planes (R-planes) to avoid running into clamps, fixtures and other obstructions that can break or damage tools, tool holders and workpieces.

Read MoreTags: Productivity, Video, Tool Wear

A useful tool for any CNC machine shop that wants to reduce costs and improve overall performance is Value Stream Mapping. Typically used as a starting point for Lean Manufacturing, Value Stream Mapping identifies and analyzes all of the activities involved in delivering a product to your customer.

Read MoreTags: Productivity, Lean Manufacturing

Haas CNC machines are built to last, but even the most rugged and reliable machine tools have parts that eventually need to be replaced. Additionally, no matter how well trained your staff is, accidents can happen. When breakdowns occur, you’ll want to get your machines up and running as soon as possible.

Read MoreTags: Productivity, Maintenance Tips

Loading bar stock manually is a tedious, time-consuming task that requires the nearly constant attention of your machine operator. As a result, you end up adding a great deal of material handling cost to each part you make. Plus, as it rotates, an unsupported bar stock creates vibrations that transfer to the spindle and may impact surface finish. Some shops compensate for this by reducing spindle speeds which, of course, adds cutting time and, again, additional cost-per-part.

Read MoreTags: Productivity

Training new employees or introducing a new process to existing employees is not a favorite pastime for most CNC shop owners. After all, if the chips aren’t flying…well you know the rest. That’s why it simply makes good sense to document procedures so that training sessions go more smoothly and employees have material to refer to on the job.

Read MoreTags: Productivity, Management

A unique feature built into the proprietary Haas control enables the company’s turning centers to save valuable seconds of tool changing time. A new video demonstrates Index-on-the-fly that reduces cycle times 5% - 15%. It accomplishes this by uncoupling the turret and allowing indexing a short distance from the tool, rather than requiring a return to the home position.

Read MoreTags: Productivity, Video

Dual spindle lathes can help boost productivity by making it possible to perform “one and done” operations, reduce setup times and make parts faster. While all of this sounds great, the idea of programming two spindles may be somewhat daunting. However Haas has made it simple through it’s exclusive control system that enables the lathe operator to enter one G code that automatically programs the second spindle by mirroring the programming of spindle #1.

Read MoreTags: Productivity, Video

Die/mold machining is often a tedious, time- and labor-intensive operation. That’s because the process usually involves multiple machine tools and handling the part 5 – 7 times. All of which adds operator cost while increasing the likelihood of damaged workpieces and inconsistent part quality.

Read MoreTags: Productivity

Investing in great CNC machine technology is one of the keys to improving productivity, especially if you’ve invested wisely in equipment that provides the best ROI. However, the quest for greater productivity doesn’t begin and end with CNC machines. There’s also the human factor to consider. Are your people as productive as they could be? If not, the first place to look for improvement is in the mirror.

Read MoreTags: Productivity, Management