Die/mold machining is often a tedious, time- and labor-intensive operation. That’s because the process usually involves multiple machine tools and handling the part 5 – 7 times. All of which adds operator cost while increasing the likelihood of damaged workpieces and inconsistent part quality.

The most common approach to die/mold machining looks like this:

- Choosing a machine strategy and programming multiple CNC machines

- “Green Machining” or roughing the part soft

- Hardening, which usually means sending the part out

- Electrode machining for secondary operations

- Using EDM for finish operations

- Completing final polish and other operations on the workbench

To accomplish all of these steps the operator must perform setups for each operation, program a series of routines, and handle the part several times. It also means spending significant money for multiple part fixtures and paying for off-site hardening.

So how do you streamline the process to increase productivity and reduce cost-per-part? By using a single, high-speed, CNC machining center that reduces the process to 2 simple steps:

- Programming the machining strategy one time into one machining center

- Using pre-hardened stock

In most cases, that’s all there is to it. EDM, bench work and outsourcing are eliminated.

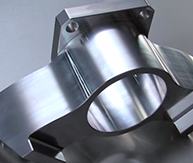

Of course, the CNC machining center must be capable of maintaining high spindle speeds and have the power, rigidity and accuracy for die/mold work. It must also have a robust yet easy-to-use control system to flawlessly execute the machining program. Additionally it helps to use proven CAD/CAM software for developing various cutting strategies, and to consult with tooling technology experts like Sandvik Coromant.

Your Torrance Haas Factory Outlet will help you choose a CNC machining center that’s perfect for your specific die/mold operations. Just call (310) 381-0750, email: jphillips@haasfactoryoutlet.com, or visit www.haasfactoryoutlet.com.