Why do you need a tailstock on your CNC turning center? It allows you to take in jobs involving parts that would be much more difficult to machine without this added feature. In this Haas CNC experts give you tailstock tips to help you expand your capabilities and reduce part costs.

Read MoreLocal News & Events | Haas Factory Outlet

Tags: Maintenance Tips, CNC Machines, Video

Universal Machine UMC-750

Five-axis machining is an effective means to reduce setups and increase accuracy for multi-sided and complex parts. The new UMC-750 universal machining center from Haas Automation, Inc., is a cost-effective solution for 5-sided (3+2) and simultaneous 5-axis machining.

Tags: Productivity, CNC Machines, 5-Axis, HFO (Haas Factory Outlet), CNC

In this video, John Nelson guides us through the Setup, Operation, and Edit modes of the latest graphical user interface of the Haas control. Well worth another look if you haven't seen this yet.

Read MoreTags: Productivity, CNC Machines, 5-Axis, HFO (Haas Factory Outlet), CNC

Workplace safety is a major concern for Haas and other the makers of CNC manufacturing equipment. We equip our machine tools with various safety components that prevent users from accessing critical areas while the machine is operating. Likewise, many loading and unloading systems employ safety cages with access doors that are locked during machining cycles, light curtains that stop machine activity when the beam is interrupted, and other safety precautions.

Read MoreTags: CNC Machines, Safety

With over 150,000 machines installed worldwide in the past 31 years, all manufactured in a one million square foot facility in Southern California, Haas has a unique place among CNC machine tool builders. The company’s success comes from listening to the needs of CNC shops, like yours, and providing high value solutions. Here are 7 facts you should know if you are considering a CNC machine investment:

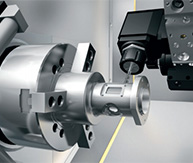

Read MoreLive tooling on CNC turning machines expands a manufacturer’s options by enabling off-center, secondary operations such as drilling, tapping and end milling on the part face and around the diameter. As you might expect, there are a number of important considerations when adding live tooling to your existing or new CNC turning machines. Here are 6 such points to think about.

Read MoreTags: CNC Machines

Investing in new equipment is no small matter for a CNC machine shop. Especially in the case of a machine tool or machining center. Making the right purchase can increase throughput, reduce your cost of operation and improve part quality and customer delivery time. So there’s a lot riding on your decision. Which means you need to ask yourself some important questions about the kind of machine you need including:

Read MoreTags: CNC Machines, Finance

Carefully monitoring costs is not a matter of choice for CNC machine shops. It’s a necessity. A modest increase in material, labor or cycle times can mean the difference between a competitive bid and a losing one. In the same way, any cost savings may help a shop win and retain customers as well as adding to the profit line on the P&L statement.

Read MoreTags: CNC Machines, Management, Finance

Turning machines with a second spindle can provide a number of benefits to CNC machine shops. For example, they enable the machine tool to automatically transfer a workpiece from one chuck to another for secondary operations such as drilling and tapping, both axially and radially. This “done-in-one” capability greatly reduces part handling, and that translates into lower cost per part. It also improves throughput and allows unattended operation. By adding automatic barfeeders and/or robotic part handling, lights out manufacturing is also a possibility.

Read MoreTags: CNC Machines

The challenges facing CNC machine shops continue to escalate, as customers demand better quality, tighter tolerances, and faster delivery. Meanwhile competition from down the street and around the globe keeps the pressure on to hold down customer costs, which impacts your profits. The solution, of course, is to optimize machine tool performance while increasing worker productivity.

Read MoreTags: Productivity, Maintenance Tips, CNC Machines