Too many CNC machine shops get caught up in the cycle of “Get the work. Do the work. Look for more work.” The most successful shops keep the job pipeline full, rather than waiting until orders run low. They generate more business by utilizing such tools as personal selling, email marketing, advertising, public relations, and a powerful Internet presence. Whether they handle these marketing efforts in house or use outside resources, they establish clear, realistic goals so they can measure their results.

Read MoreLocal News & Events | Haas Factory Outlet

HFO Torrance

Recent Posts

Tags: Marketing

A popular feature on the Haas CNC Web site is the Tip of the Day video series. In the Haas IMTS 2016 booth (S-8100) you can meet Tip of the Day presenter, Mark, as he performs live demonstrations of information that can help you get the most from your Haas CNC machines. Mark also encourages you to bring your questions and ideas for future Tip of the Day videos to the booth.

Read MoreTags: Events, IMTS (International Manufacturing Technology Show)

By nature, CNC machine shop owners tend to be practical people. After all they spend their days making quality parts or products for their customers. They also invest in new technology and competent employees. With a lot of hard work and no small sacrifice they build a successful business, and often hope to bring in their children or other family members as next generation owners.

Read MoreTags: CNC Machine Shops, Management

Adding live tooling to existing CNC turning machines or including this function for a new machine tool purchase makes a great deal of sense if you want to improve productivity by reducing part handling for multiple operations. Live tooling enables off-center, secondary operations such as drilling, tapping, and end milling on the part face and around the diameter. As is the case whenever thinking about machine tool options, you’ll want to consider a number of factors so you can make the best decision. Here are five basic issues to consider:

Read MoreTags: CNC Machines

The cost of owning and operating a CNC machine is much more than the initial purchase price. It also includes the routine maintenance any machine requires. If technical service and replacement parts are not readily available, you can add the expense of excessive downtime to your overall cost. That’s why Haas CNC and your Milwaukee Haas Factory Outlet provide all of this and more:

Read MoreTags: HFO (Haas Factory Outlet), Finance

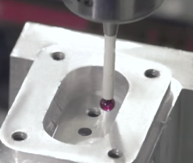

How Wireless Probe Technology Reduces Setup Time & Reduces Tool Expense

Posted on Aug 12, 2016 12:00:00 AM

In this video Haas demonstrates the new Wireless Intuitive Probing System (WIPS) for Haas CNC machine tools. Fully integrated within the Haas control, this system makes it easy for operators to perform quick setups and in-process inspection, and detect broken and worn tools.

Read MoreTags: Video, Probes, WIPS (Wireless Intuitive Probing System)

Training new employees or introducing a new process to existing employees is not a favorite pastime for most CNC shop owners. After all, if the chips aren’t flying…well you know the rest. That’s why it simply makes good sense to document procedures so that training sessions go more smoothly and employees have material to refer to on the job.

Read MoreTags: Productivity, Management

Because of the differences in their basic structures, composites react differently than metals during machining. Whereas we cut most metals by shearing away parts of an essentially uniform structure, machining composites involves cutting through the layers of its various materials. Each of these layers reacts differently to the action of the cutting tool.

Read More- Automating material loading and part unloading. Whether you’re machining bar stock or blanks, reducing the involvement of the machine operator saves considerable labor cost and frees the operator to manage multiple machines. For example, automatic bar feeders safely and reliably load bar stock and reduce vibration in the cutting zone, while palletized systems and robots efficiently load and unload even very large and heavy parts.

- Customers demand agile manufacturing. Many CNC machine shops are asked to perform short runs, handle large families of parts and quickly adjust to product design and material changes. Plus customers expect rapid responses to any changes. Responding to these demands requires flexible, versatile machine tools and accessories.

- Customers want solutions, not just new machines. With the demand for agile manufacturing comes the need to quickly adapt to new machining challenges. For example, working with difficult-to-machine materials like titanium requires an understanding of both machine tool capabilities and optimum tooling choices. Your Torrance Haas Factory Outlet can help you with both.

- Better equipment maintenance. As CNC machine shops add more advanced machine tools and accessories, they have an increased need for predictive and preventative maintenance. Moreover, with customers demanding faster turnarounds and greater agility, equipment failures can create major problems. Plants need planned preventative maintenance programs, either developed internally or provided by a trusted supplier like your Torrance Haas Factory Outlet.

- Lights out manufacturing. To keep up with customer demands many shops operate multiple shifts, which can drive up labor costs. Running an unattended overnight shift is one proven labor saving strategy. However achieving efficient lights-out production is not as simple as we might think. Your Torrance Haas Factory Outlet can guide you through the process. Simply call (310) 381-0750, email: jphillips@haasfactoryoutlet.com, or visit www.haasfactoryoutlet.com.

Tags: CNC Machine Shops

Changing machine tools is always a challenge for operators who are comfortable with a process they’ve used for a long time. However the many advantages of CNC machining, including reduced cycle time, faster throughput and lower cost-per-part are hard to ignore.

Read MoreTags: CNC Machines, Video