Feeling the pinch on labor costs? Want to see those profit margins skyrocket?

If you answered yes to any (or all) of those, then you NEED to be at our Open House Automation Event at Haas Factory Outlet Pittsburgh! We’re talking about cutting-edge tech that’ll transform your operation and help you CRUSH your manufacturing goals.

Register today to unlock your full manufacturing potential with automation.

When: Wednesday, May 15, 2024

Time: 10:00 am - 2:00 pm

Lunch will be provided.

These machines will make an appearance:

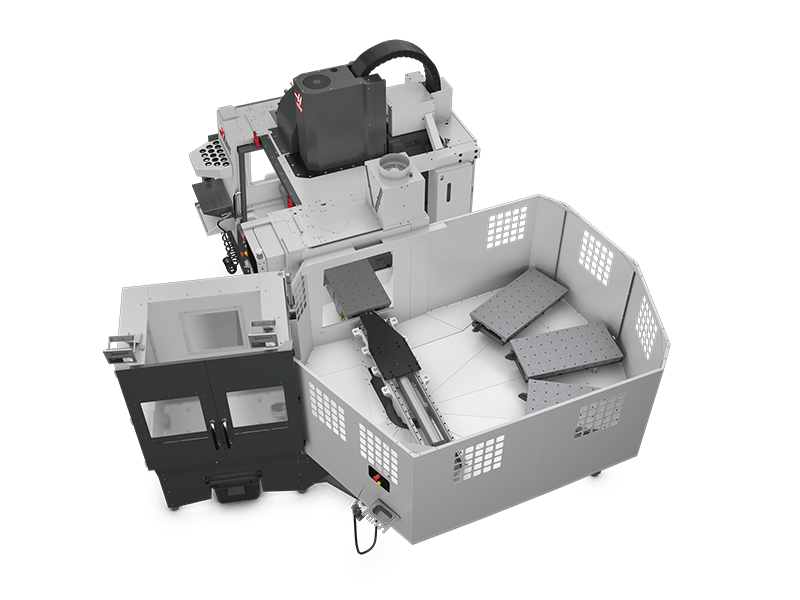

UMC-500

The shorter travels and compact footprints of the Haas UMC-500 Series Universal Machining Centers make them perfect solutions for 3+2 machining and simultaneous 5-axis machining of smaller parts.

UMC-750

The UMC-750 has an integrated dual-axis trunnion table with a 500 mm diameter platter that features standard T-slots and a precision pilot bore for fixturing versatility. The trunnion provides +120 and -35 degrees of tilt and 360 degrees of rotation to provide excellent tool clearance and large part capacity.

VF-2SSYT

with Pallet Pool

Every VF Series vertical machining center provides outstanding features at an excellent price, and features a wide range of available options to customize your machine to your exact needs. The VF-2YT offers more Y-axis travel than our standard VF-2.

VF-2SS

with AWR VBX-160

The high-performance Haas VF-2SS provides the high spindle speeds, fast rapids, and quick tool changes necessary for high-volume production and reduced cycle times.

The VBX Series is a machine tending solution for vertical CNC mills that is easy to use, versatile, and reliable. The patented MultiGrip™ workholding allows you to automate multiple OP10/OP20/OP30 part numbers in high-mix, low-volume manufacturing.

ST-15Y

with Robot Package 7KG

The ST-15Y is an extra-small footprint, big-bore lathe with a generous work envelope. The addition of Y-axis and live tooling allows milling, drilling, and tapping for increased machine capabilities. This machine offers the best performance for the money in its class.

The Haas Robot Package-7kg is a fully integrated, plug-and-play, 7 kg capacity robot system for Haas machines. Includes: 6-axis robot, mounting stand, software interface for direct control through the Haas machine, electrical interface box, interface for area scanners or light curtains, and more.

ST-20Y

with APL

TM-0P

The TM-0P is the smallest and most affordable of the Haas TM-P Series Toolroom Mills. Haas TM-P models are affordable and easy to use and offer the precision control of the Haas CNC system.

Super Mini Mill

The completely redesigned Mini Mill is enhanced with all-new FEA-optimized base and column castings, larger travels, and faster spindle speeds and rapids for increased production output.

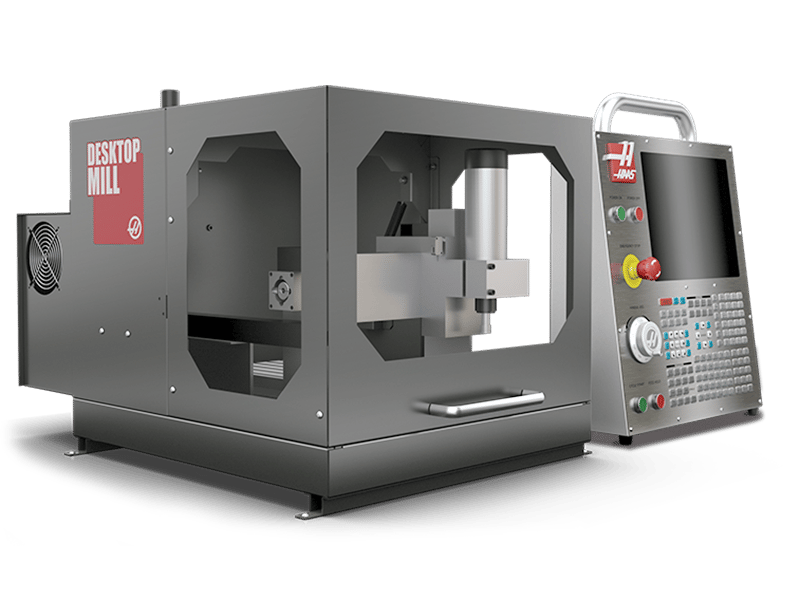

Desktop Mill

The Haas Desktop Mill is the ultimate training machine for schools and technical colleges. Perfect for teaching the basic principles of programming and operating a CNC mill. Designed to cut plastics and machinable wax, it is also perfect for hobbyists and benchtop machinists.

DS-30Y

with Bar Feeder

The DS-30Y Y-axis turning center combines dual-spindle turning with Y axis, C axis, and live tooling to create a powerful “done-in-one” machining solution for any shop. The DS-30Y has a medium footprint, yet provides a generous work envelope. This machine offers the best performance for the money – the best value – in it’s class.

The Haas Bar Feeder is a simple and affordable way to automate part production on Haas turning centers to boost productivity. It is designed and built exclusively for use on Haas turning centers, and connects directly to the Haas control.

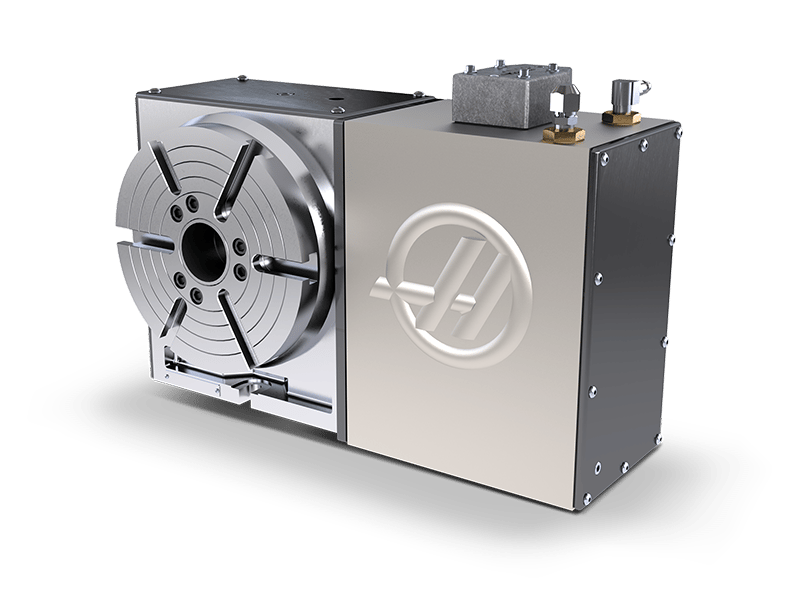

HRT-210

For holding medium to large parts or fixtures, the HRT Series of T-slotted rotary tables is the answer. These rugged, heavy-duty tables can be mounted vertically or horizontally for added versatility. Chucks and fixtures can easily be bolted to the table using the six precision T-slots, and large through-holes allow for bar feeding and special fixture-locating requirements.

AWR RC

The AWR RC is an automated machine tending system for your CNC lathe. The RC is compact and has flexible templates to accommodate small or large parts. Equipped with video instructions that are easy to understand, no robot programming or experience is needed.

The New Redesigned Haas Mini Mill!

More Mill Than Mini?

The Mini Mill has been completely redesigned and Mike gives us a quick break down on all the improvements we've made. The new Mini Mill is enhanced with all-new FEA-optimized base and column castings, larger travels, and faster spindle speeds and rapids for increased production output. An all-new Y-axis washdown nozzle improves chip flow inside the machine, and a new 45-gallon (170-liter) external coolant tank simplifies maintenance.